Top-Mounted Magnetic Level Gauge เกจวัดระดับแม่เหล็ก สำหรับติดตั้งด้านบนถัง

Magnetic Level Gauge เกจวัดระดับของเหลวสำหรับติดด้านบนถัง ตามหลักการลอยตัวของลูกบอลแม่เหล็กซึ่งอยู่ในตัวมาตรวัดจะขึ้น-ลงตามระดับของของเหลวภายในถัง เมื่อลูกบอลเคลื่อนผ่านแถบสี(จะมีสองแถบสี เช่น ขาว,แดง) จะผลักให้เปลี่ยนเป็นอีกแถบสี ซึ่งทั้งสองแถบสีจะเปลี่ยน

คำอธิบาย

ข้อดี

1. มีความแม่นยำสูง โครงสร้างที่เรียบง่าย มีความเสถียร สามารถมองเห็นได้จากระยะไกล

2. ไม่ขึ้นกับสถานะทางกายภาพและทางเคมีของตัวกลาง เช่น การนำไฟฟ้า ค่าคงที่ไดอิเล็กตริก โฟม เป็นต้น

3. ใช้ได้กับสภาพแวดล้อมขนาดกลางทุกชนิด เช่น สารกัดกร่อน สารพิษ และวัตถุระเบิด

4. วัดส่วนต่อประสานหรือการวัดระดับของสื่อ 2 ชนิดที่มีความหนาแน่นต่างกัน

5. สัญญาณเอาท์พุต 4 ~ 20mADC สองสาย, 0.8 '' หรือ 0.56” จอแสดงผล LED ดิจิตอล ของมาตรวัดระดับแม่เหล็กแบบดิจิตอลที่ติดตั้งด้านข้างอัจฉริยะ

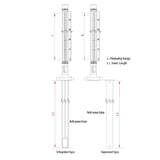

Installation

Magnetic level gauge เกจวัดระดับของเหลวประเภทนี้สามารถติดตั้งได้หลากหลาย เช่น ติดตั้งด้านข้าง, ด้านบน หรือแบบอื่นๆ

Component

1. Flange connection: หน้าแปลนเชื่อมต่อด้านข้างถัง

2. Transmitter: ตัวส่งสัญญาณ 4-20mA

3. Level switch: Alarm Switch สามารถปรับระดับตามการใช้งาน

4. Structure: ส่วนเชื่อมด้านบน-ล่าง

Applications

Magnetic level gauge ใช้กันอย่างแพร่หลายในอุตสาหกรรมปิโตรเลียม อุตสาหกรรมเคมี แหล่งน้ำมัน อุตสาหกรรมยา อาหาร อุตสาหกรรมไวน์ ฯลฯ เหมาะสำหรับการวัดระดับภายใต้สภาพแวดล้อมของอุณหภูมิสูง/ต่ำ ความดันสูง การกัดกร่อนและความเป็นพิษ

ข้อมูลทางเทคนิค

| Center-center distance | 150~6000mm |

| Density | >0.45 g/cm3 |

| Working Pressure | PN2.5~PN420(x0.1MPa) |

| Material | SS304, SS316L, PP, 304+PTFE |

| Temperature | -190~425°C |

| Process Connection | Flange DIN, JIS, ANSI |

| Upper End | Welding cap (standard) For more, see note 2 |

| Lower End | Flange cover (standard) For more, see note 3 |

| Optional-limit level switch | SPST/SPDT 60W 1A 250VAC(standard) |

| Optional-level sensor | 4~20mADC output(standard) |